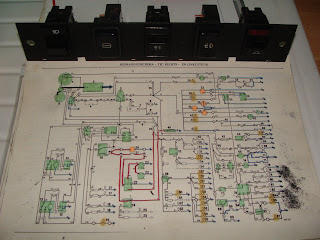

I had the car out of the garage last weekend to test

the engine temperature and the electric cooling fan.

Somebody on the TR7 site was showing off with his garage

floor so therefore a few pictures of the work I’ve been

doing during the summer.

All was well just until the moment I wanted to start the

car to get it back in to the garage; no kick or movement

from the starter.

I was thinking about Beans ( http://tr7beans.blogspot.com/ )

last time; he spent so much time and effort on to his car

and then somebody almost crashed in to it and later on

during the 10 countries trip his gearbox breaks down;

how much bad luck can someone take?